The structure of the self-adhesive material consists of three parts on the surface, namely surface material, adhesive and backing paper. However, from the perspective of manufacturing process and product quality, the self-adhesive material consists of seven parts:

1. Back coating or printing

Back coating (back printing) is a protective coating on the back of the backing paper to prevent the adhesive around the label after waste discharge and rewinding from sticking to the backing paper. Another function is to create multi-layer labels.

2. Surface coating

Used to change the surface properties of surface materials. Such as improving the surface tension, changing the color, adding a protective layer, etc., to make it better accept the ink and easier to print, to prevent dirt, increase the adhesion of the ink and prevent the printed graphics from falling off.

3. Surface material

It is a material that accepts printed graphics and text on the front side, accepts adhesive on the back side, and is finally applied to the object to be adhered. Generally speaking, any flexibly deformable material can be used as a self-adhesive material.

4. Adhesive

The adhesive is the medium between the label material and the bonding substrate and plays a connecting role. According to its characteristics, it can be divided into two types: permanent and removable.

5. Release coating (silicon layer coating)

That is, a silicone oil layer is coated on the surface of the backing paper. Coating the silicone oil can make the backing paper have a very low surface tension and a very smooth surface. The function is to prevent the adhesive from bonding to the backing paper.

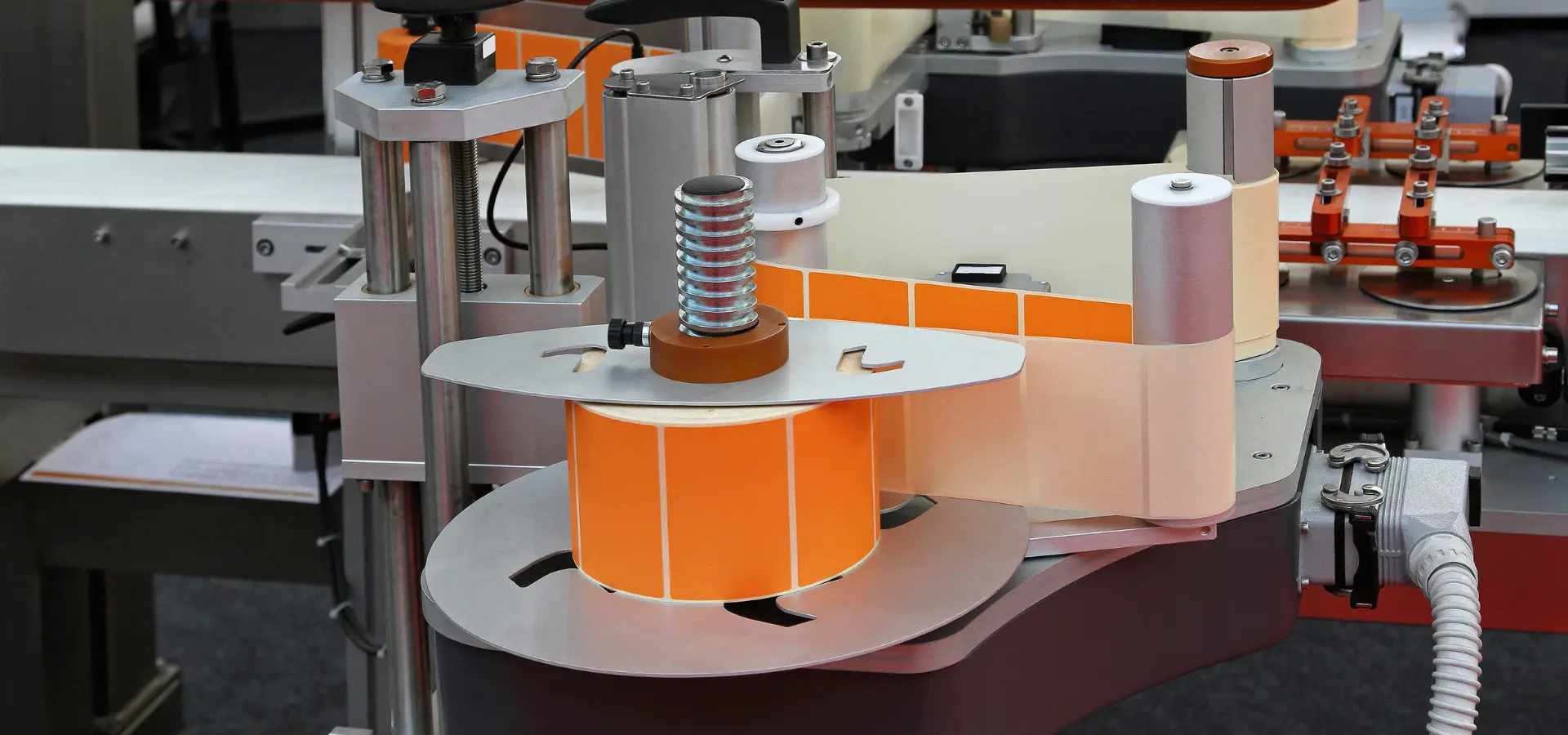

6. Bottom paper

The function of the backing paper is to accept the release agent coating, protect the adhesive on the back of the surface material, and support the surface material so that it can be die-cut, waste discharged and labeled on the labeling machine.

7. Apply bottom layer

It is the same as the surface coating, but it is coated on the back of the surface material. The main purpose of the bottom layer is to protect the surface material and prevent the adhesive from penetrating; to increase the opacity of the fabric and increase the gap between the adhesive and the surface material. The adhesive force; prevents the plasticizer in the plastic surface material from penetrating into the adhesive, affecting its adhesive performance, causing the label's adhesive force to decrease and the label to fall off.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id

.webp)

.webp)